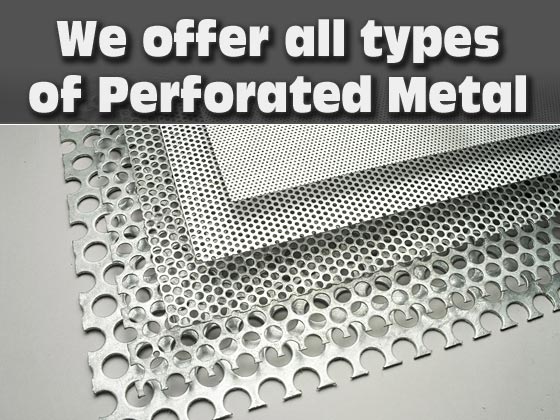

Perforated Metal

Perforated Metal comes in a selection of hole shapes, sizes, gauges and material types, used in a variety of applications like screens, guards, panels, partitions and enclosures

To place an Order or get a Quote: Quote/Order Form

Perforated Metal can take many shapes with numerous choices of perforations. The perforating process is perfectly adaptable to provide surprisingly satisfying design solutions, enhancing the look as well as the performance. Perforated components make products work better with holes that function several ways. Perforated metal parts work more efficiently because the perforating process is so adaptable to the designer’s requirements for perforations and their placement, material specifications and the shape of the finished part.

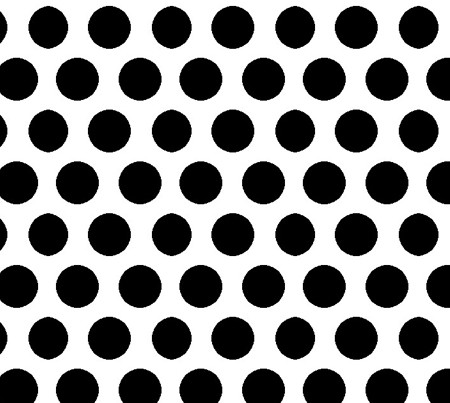

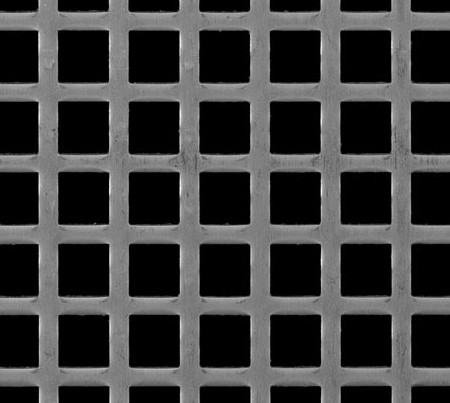

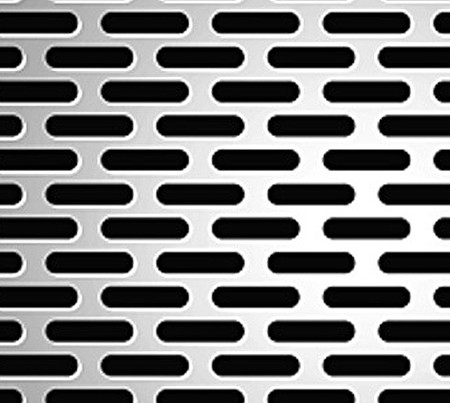

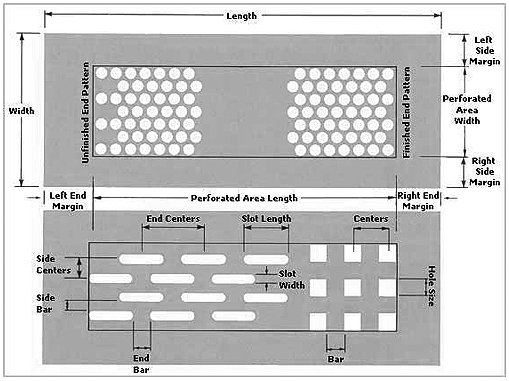

Perforated Metal Diagram:

Applications:

- Filters

- Guards

- Lighting Fixtures

- Acoustic Panels

- Shelving

- Food Processing

- Vents

PRODUCT DEFINITIONS, TERMS AND SPEC INFORMATION:

Perforated Metal

- Very versatile and functional depending on its shape opening and gauge and sixe

- Can be strong depending on gauge

- Can vent, screen and filter a variety of solids

- Is lightweight but durable

- Its openings can be chosen for optical requirements appealing to to variour architectural requirements

- Perforated Metal also helps to diffuse light and air. If manufacturing a product that needs to be lighter, for the right product application, use perforated metal — metal sheet retains a high percentage of it’s strength after it’s perforated but loses a lot of costly weight.

Important Terms for Perforated Metal:

- Perforations

- Round Perforations: Staggered (60 degree pattern) is standard.

- Variations include 45 degree staggered, and straight line pattern.

- Square Perforations: Staggered or straight line pattern.

- Slotted Perforations: Side staggered, end staggered, or straight lines.

- Slotted perforations will be round end slots; specify if square end slots are required.

- Other Perforations: Available upon request.

Spacing Perforations

Spacing for large perforations will be designated be either Centers of perforations, or by the Open Area required. Spacing for small perforations will be designated by either Centers, or Open Area, or if more practical, by the Number of Perforations to the Square Inch.

Pattern of Perforations

- Staggered Perforations, both Round & Square: Direction of the stagger will normally be the short dimension of the sheet. Straight row of hole is normally parallel to long dimension of sheet.

- Slotted Perforations: The long dimension of the slots can be furnished with either the width or length of the sheet in most cases.

Margins

- Perforated Stock Size Sheets & Plates: The long sides of the sheet will be supplied with minimum margins. The short sides of the sheet will have either minimum margins or no margins.

- Sheets & Plates Re-sheared after Perforating: Special margins are available to specifications but they must carry a tolerance within the limits of the perforating tool.

Unfinished end pattern is standard in the industry.

Flatness of Sheets & Plates

In the majority of requirements, perforated sheets or plates can be furnished to AISI flatness tolerances. Before ordering any of the following special requirements, discuss then with our sales department:

- Perforated sheets with extra wide margins.

- Blank areas required within the perforated area.

- Perforated sheets with very large percentage of open area.

- Heavy gage metal in relation to the size of the perforation.

- Special alloys.

- Stretcher leveled sheets.

Guidelines for Minimum Hole Size/Minimum Bar Width

The rule of thumb for perforating is that the hole diameter should not be less than the thickness of the material. The closer to a 1-to-1 ratio, the higher the probability of tool failure and the greater the precautions necessary to avoid it. Modifications can be made in certain instances at additional costs. For stainless steels and similar higher strength materials, it is preferable to specify at least three thickness gauges thinner than hole diameter.

The same general rule applies to bar width. The bar width should be greater than material thickness because of the increased number of punches and therefore, increased perforation tonnage. The bar width can be adjusted at increased costs.